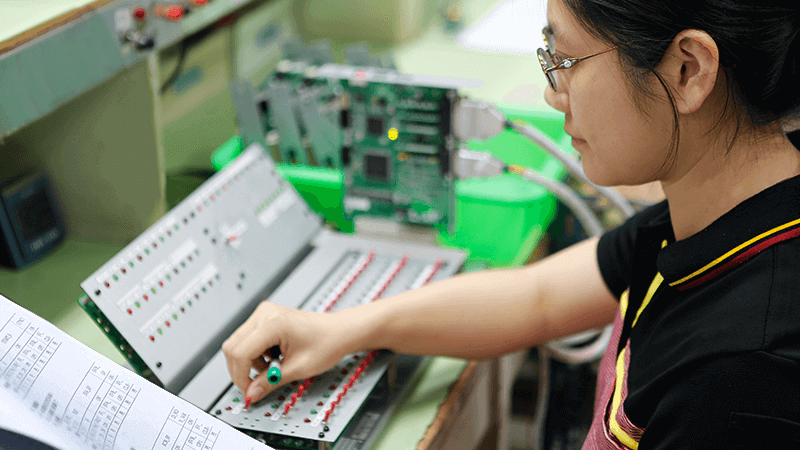

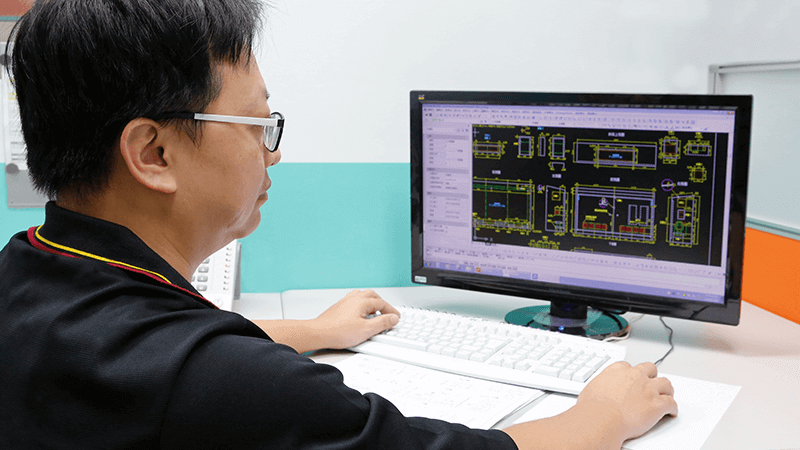

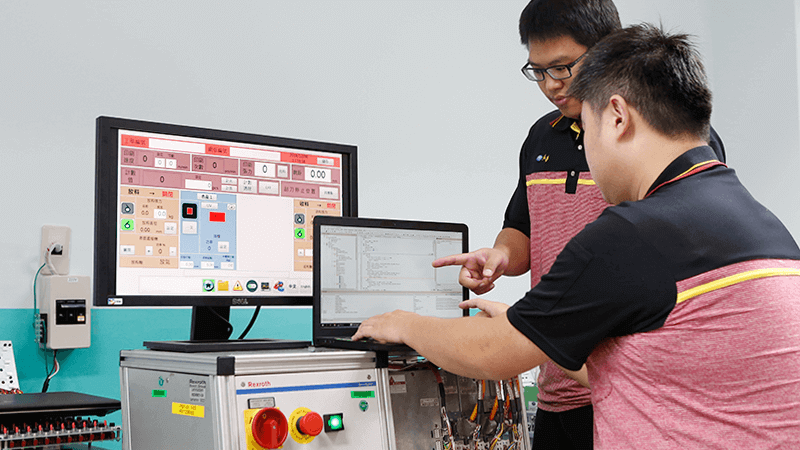

Our ACS solutions span across machines of several industries, including plastic and rubber, woodworking, metal machining, and printing.

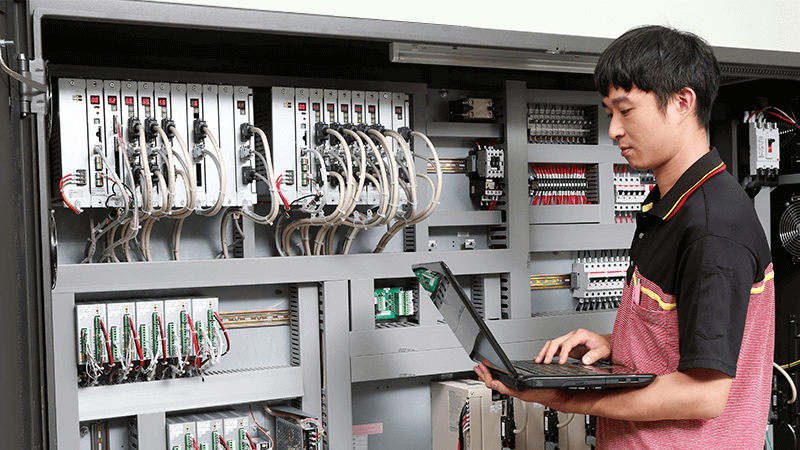

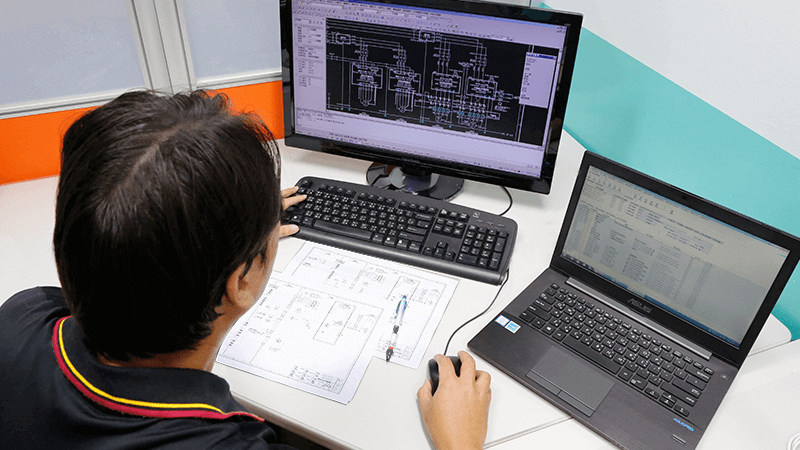

Our core control technology competencies include electronic cams, phase synchronization, multi-axis synchronization, positioning, tension control,etc.

These technologies improve precision and production efficiency, effectively reducing unnecessary devices in mechanical structural design and lowering machinery costs.

Our solutions meet the highest international standard and can be certified through the following standards as requested:

English

English  繁體中文

繁體中文